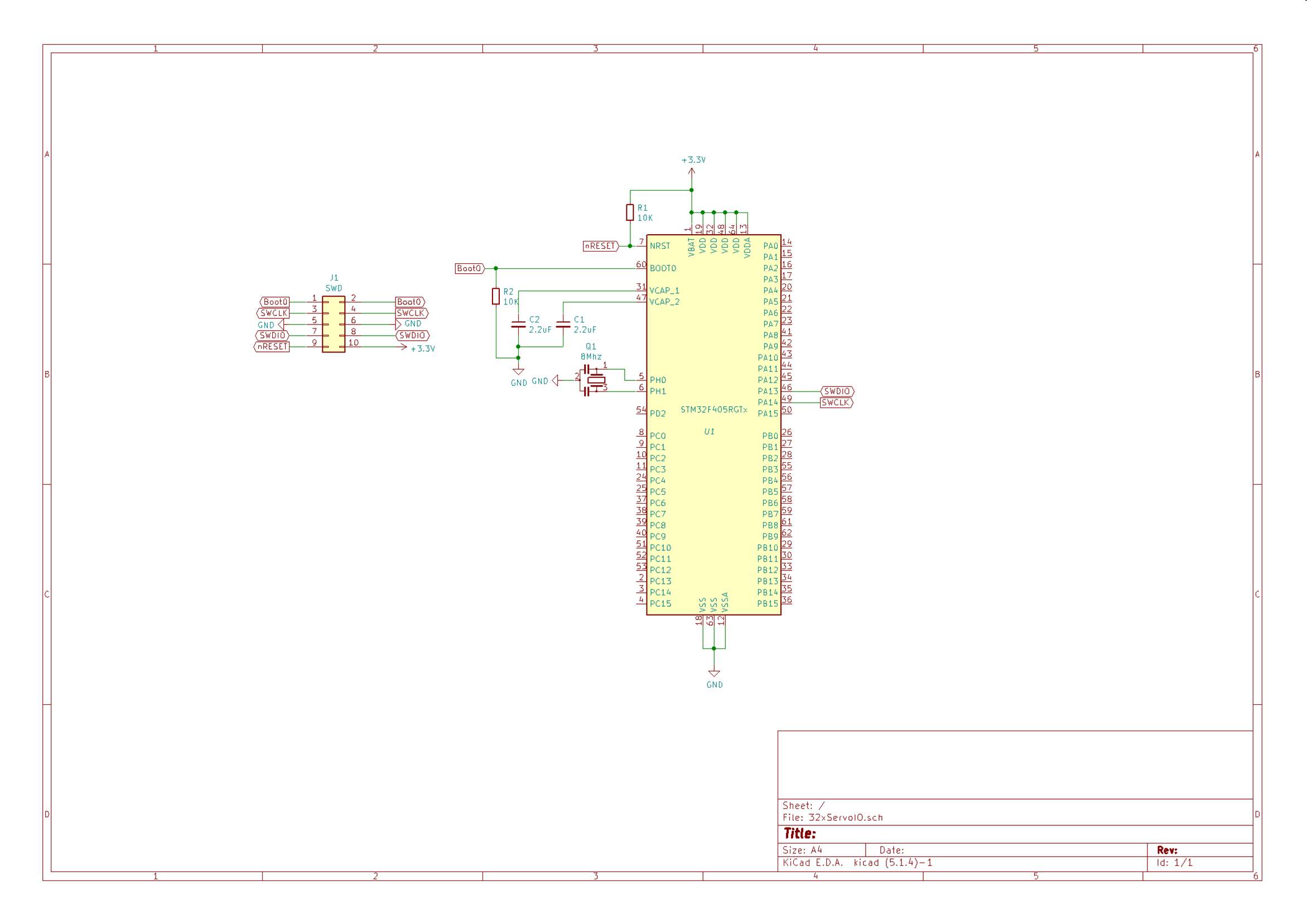

The graphical user interface on KiCAD is different than most applications. On KiCAD you get little feedback that you have selected something. Editing on PCB is quite “normal” – you select a component and click to move it. Doing the same on schematics are different, you select by using area and the component stick to cursor until you click again.

This is just one example of how KiCAD interface is a bit different than what you would expect from a standard Windows application. And this takes a bit of time to learn.

Comparing to Target 3001 it is a few things that are automated in Target and manual in KiCAD, but the rest is quite cool if you take the time to master the tools.

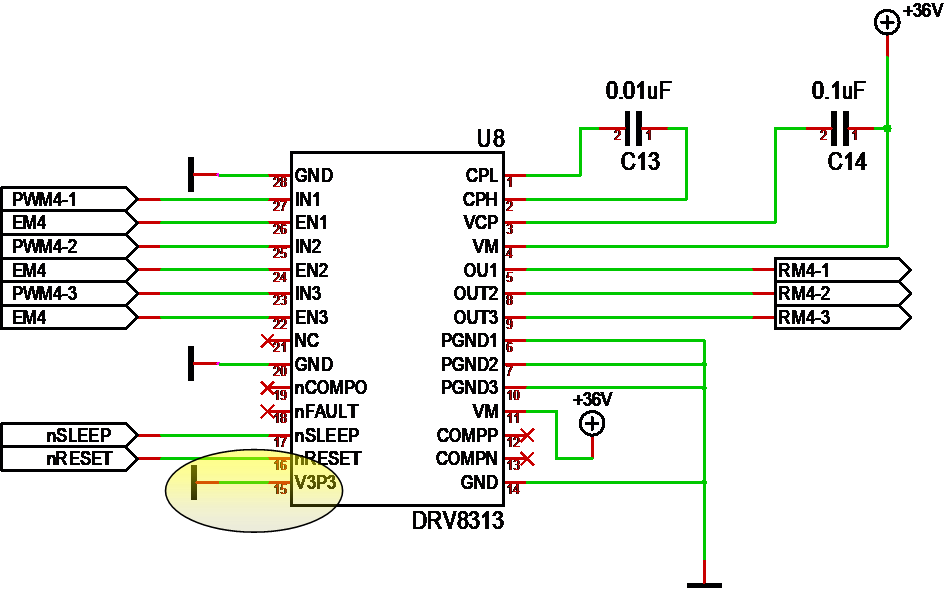

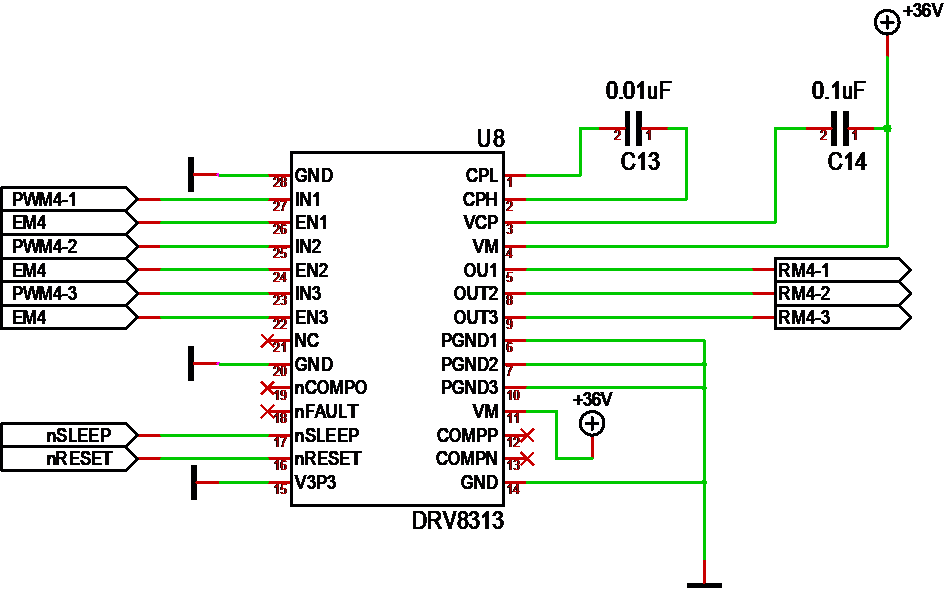

Target 3001 have multiple sheets with global labels, but KiCAD have a hierarchical sheet system. I basically use the first sheet for sub-sheet for every module in the system. But, here comes the main advantage – they are actual modules. KiCAD support local tags that can be used as interface if you re-use the component. This is a big advantage – I am about to redraw 32xServo/IO and can basically have one schematics referenced 32 times.

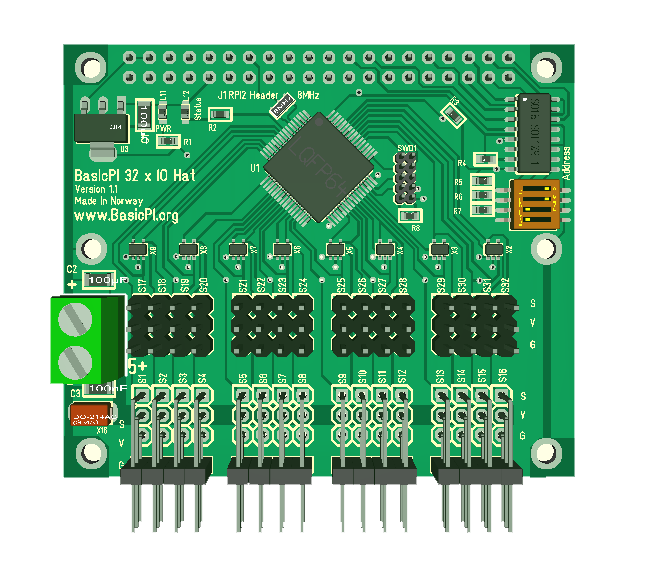

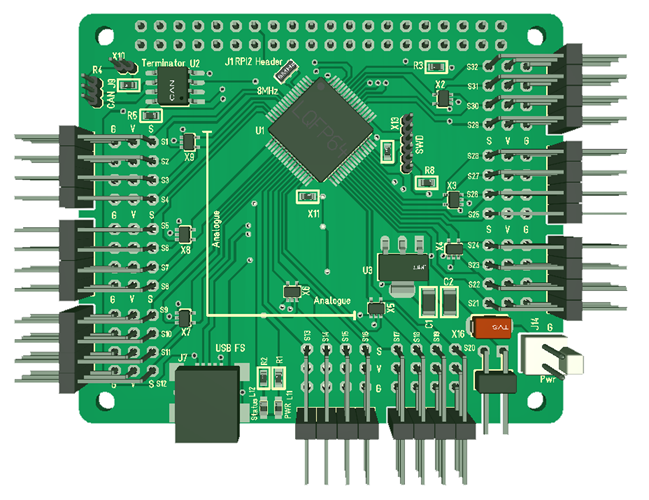

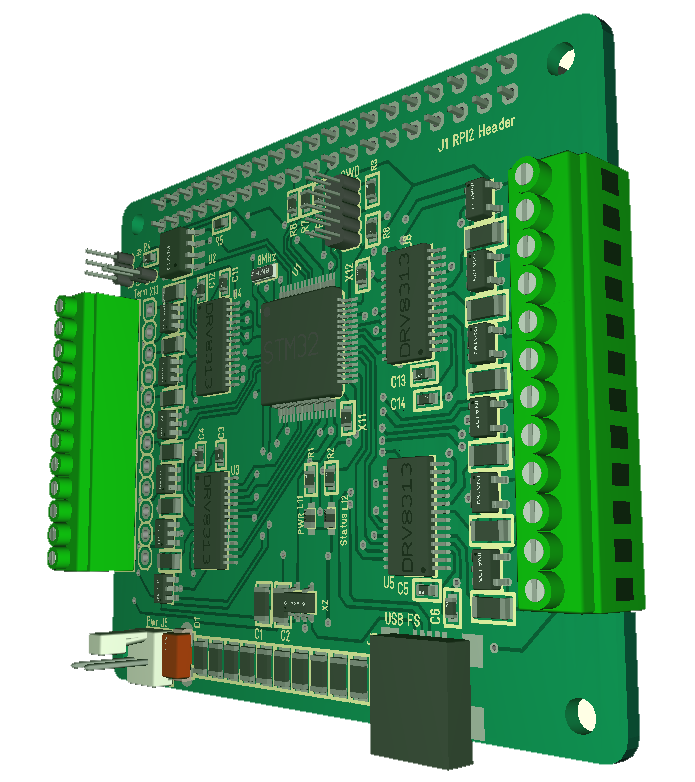

Integration between Schematics, PCB design and 3D View is close to fully integrated. It is separate applications, but you don’t notice that so much. What was most alien is that in KiCAD you draw schematics, afterwards you allocate footprints – so in other words you can easily change footprint without touching schematics. In Target 3001 symbol, footprint and 3D was always connected – it’s pros and cons on both – you just need to get used to the tool in front of you.

All in all I am quite impressed with KiCAD so far. Yes it takes a bit of time to learn, but many of the differences leads to more advanced tools that will help productivity. Using KiCAD without a community and dozens of videos would however have been very difficult.

Moving lines on schematics or PCB seems to be little automated, but it might be that I have not learned it properly yet. If I should compare Target 3001 and KiCAD I would state that Target 3001 is much easier to learn and master than any other tool I have tested so far. I do however feel that KiCAD will be better and faster to work with once you take the time to master it – and this is what matters because we are only newbies for a short time.

And lets not forget the most important feature in KiCAD – it is free. If I should continue with Target 3001 I would need to pay 1000.- USD for a fraction of what I got in KiCAD – which I can guarantee you is not an option. I have a friend using Cadence priced to something like 10,000.- USD per license and he brags about it a lot. But, I also remember a time then Embedded IDE’s JTAG’s and compilers costed thousands of dollars – I still pay license on Visual Studio at work, but even that is free for open source these days.