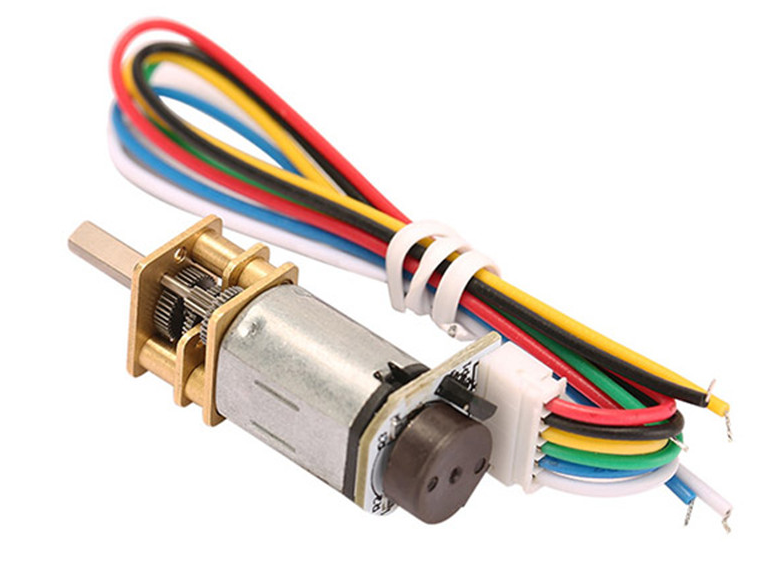

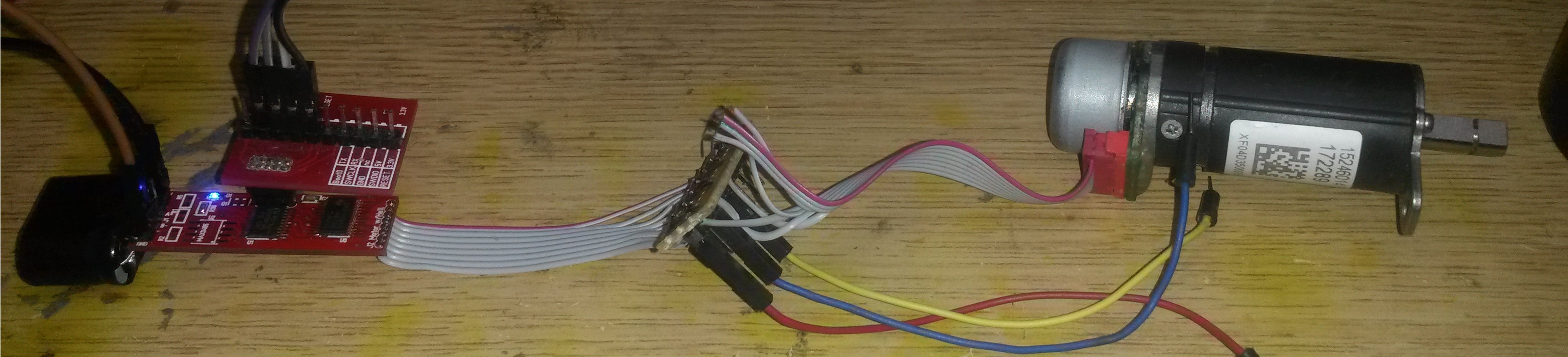

This is a classic N20 DC motor With gearbox and a Encoder. I made a micro stand-alone Control system for these, but I did not support the Encoder. The Encoder will send pulses back as the motor run indicating speed and relative position allowing us to use this as a small stepper motor.

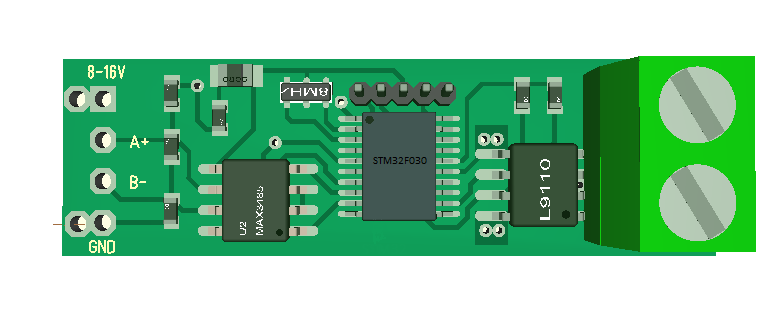

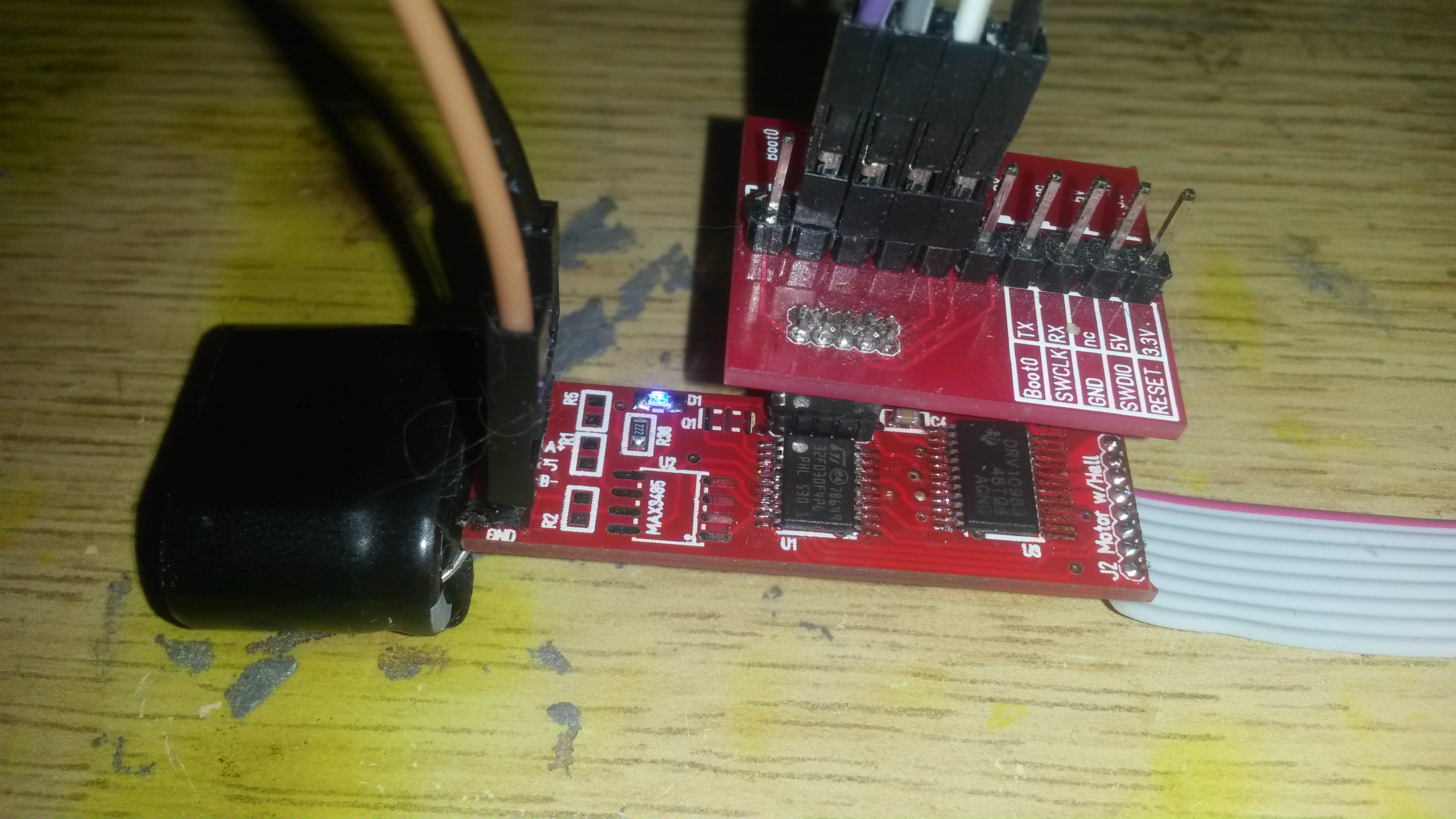

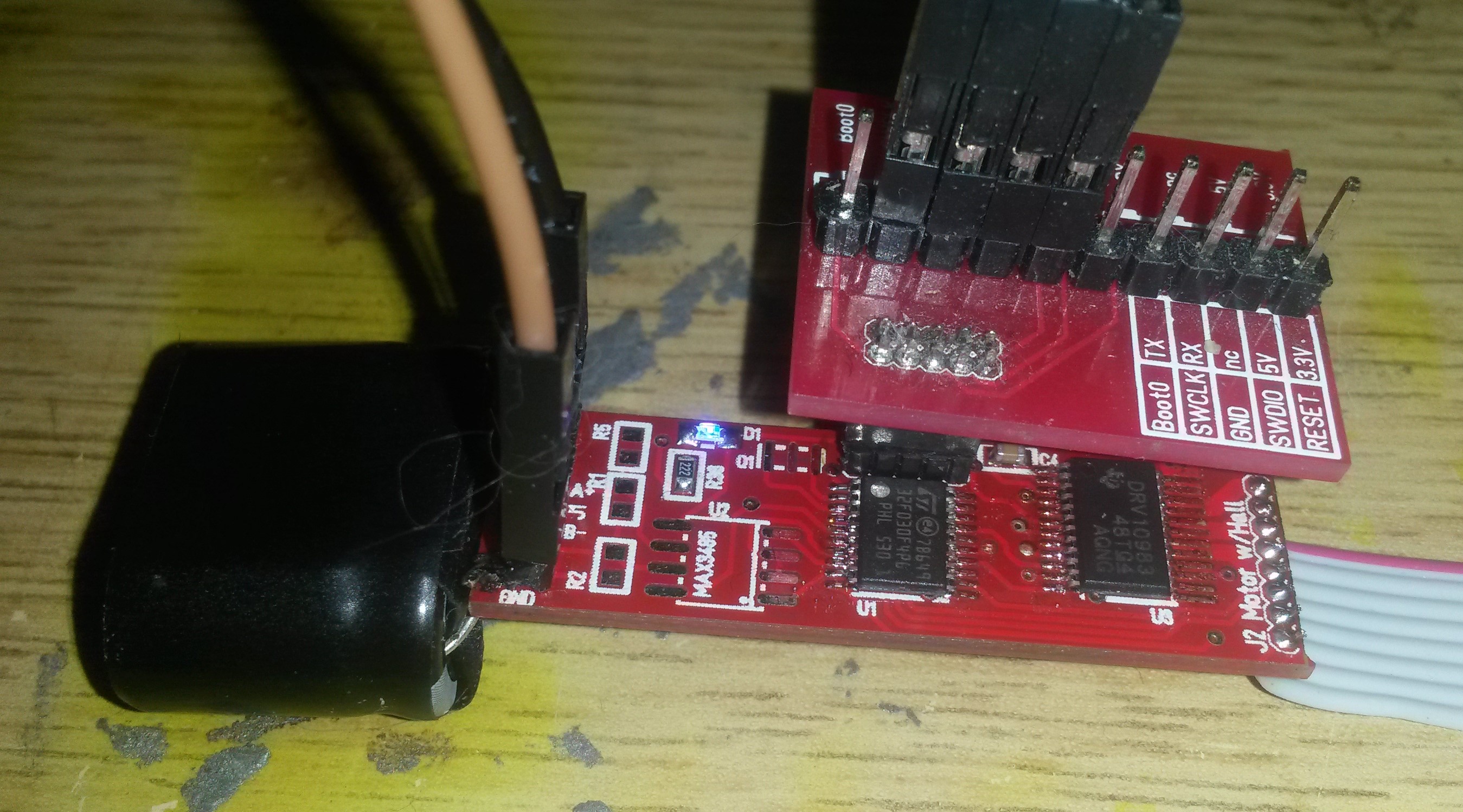

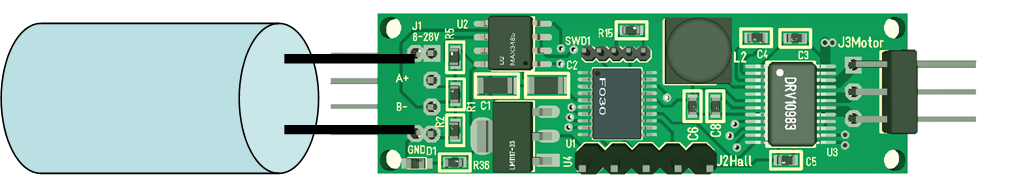

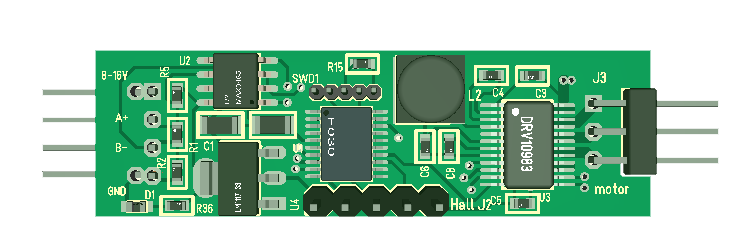

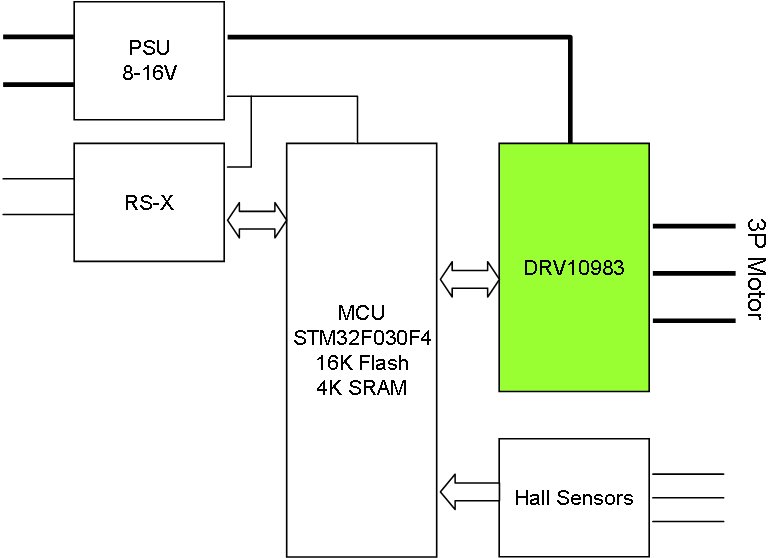

My micro DC motor Controller was a bit booring – it just worked 🙂 – in this case I want to replace the screw terminal and add support for the Encoder. I have plenty spare pins. The only difficult issue here is the size. But, I think I will dig in on 50 x 15 millimeters With mounting holes so I get all components on one side.

I also need to re-visit my mini PWM generator and Sensor for the same reasons – Connectors and mounting holes. I admit I focused a bit too much on size alone then I made these.

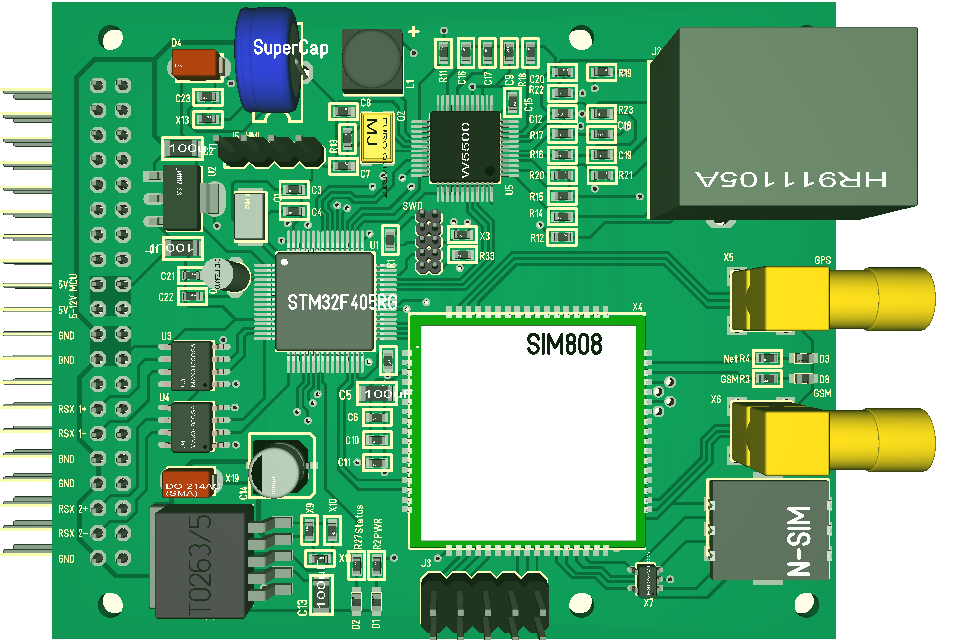

Another Component is to make a ESP32 With battery capable of switching on/off these as well as operating them – I need to think about that a bit because I could also just use the ESP32 and add the size needed replacing the STM32F030.