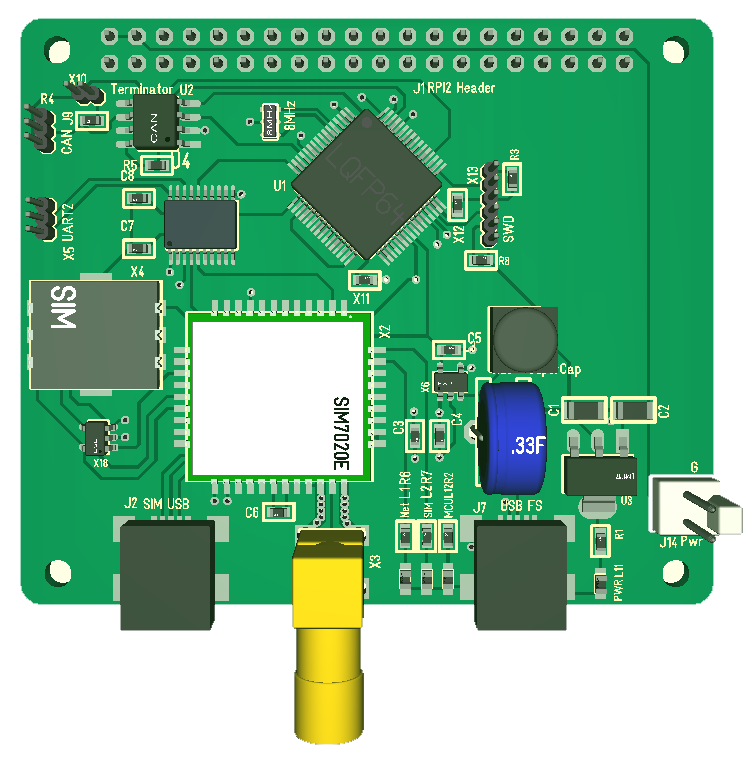

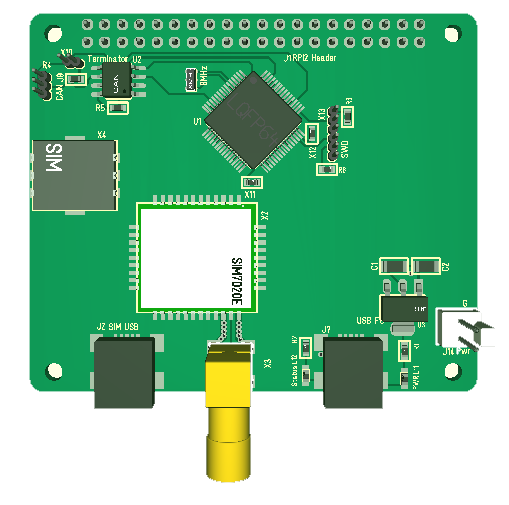

SIM7020E is a small module that offer 4G services and access to the new NB-IoT service that is available to give access to remote sensors that earlier was not possible. All-in-All this is just a new wrapping on a service that have been available since GSM and can be achieved with several low cost modules. The difference with NB-IoT is that is support better latency/cost schemes.

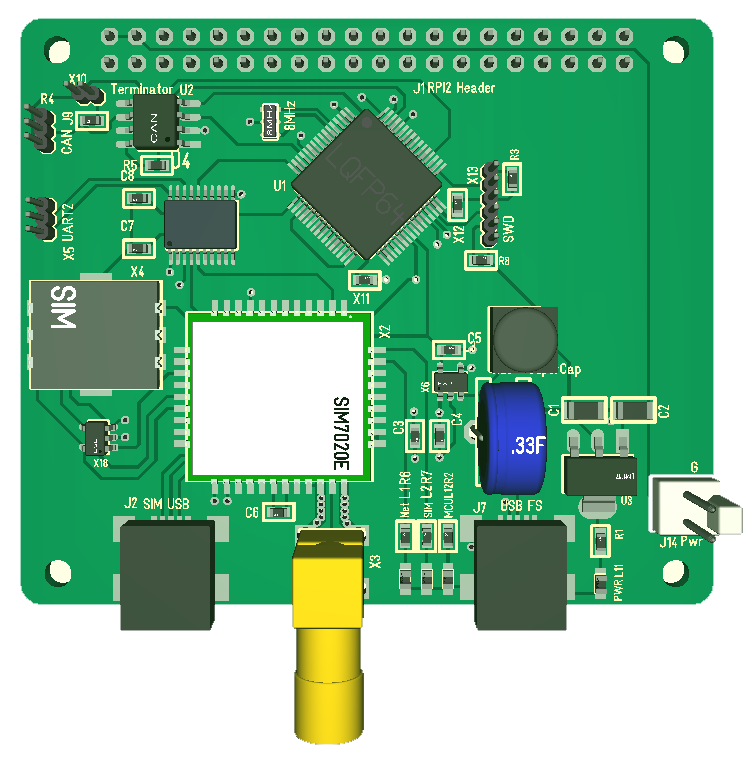

I really would have preferred to put 4G, GPS and LoRa on one Hat, but I will run into space and antenna issues so the 4G module will be on it’s own.

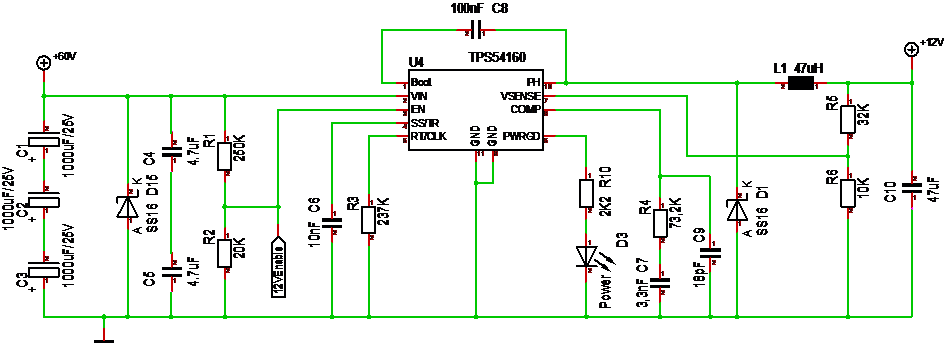

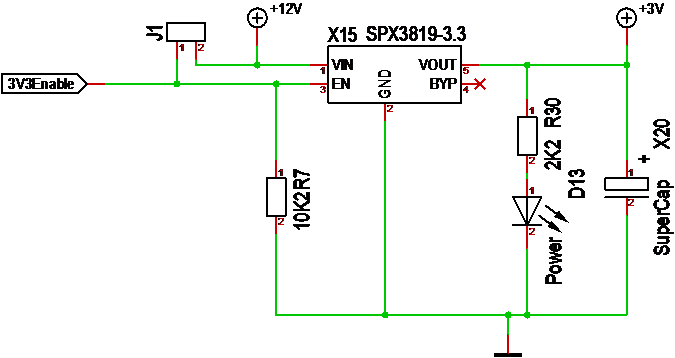

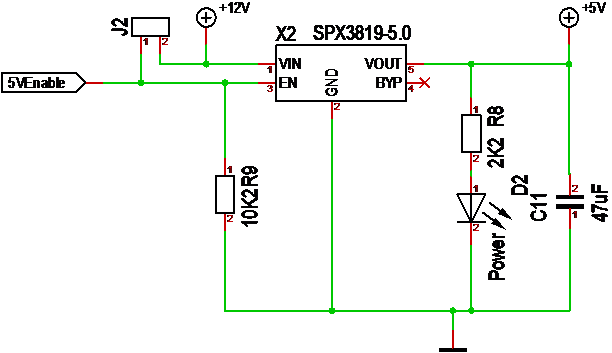

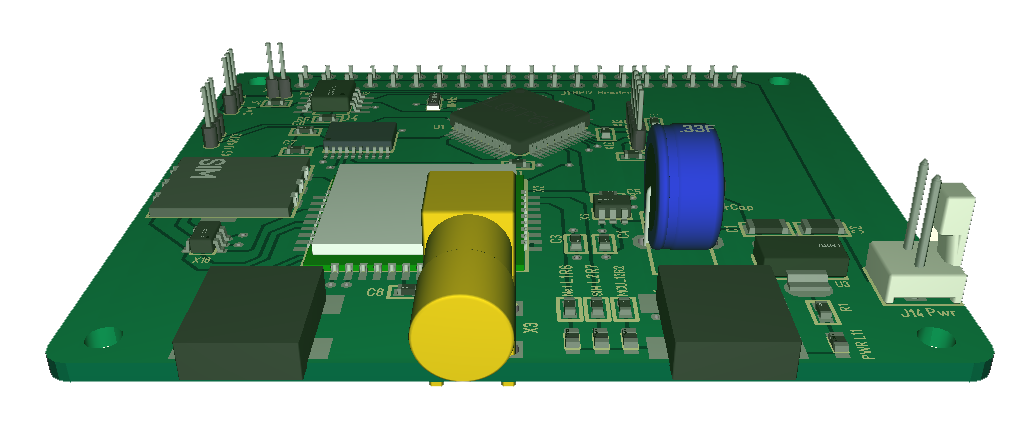

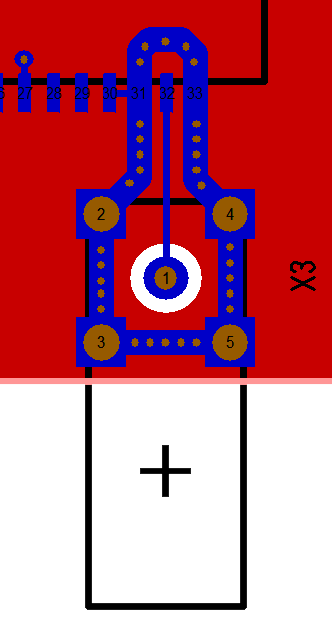

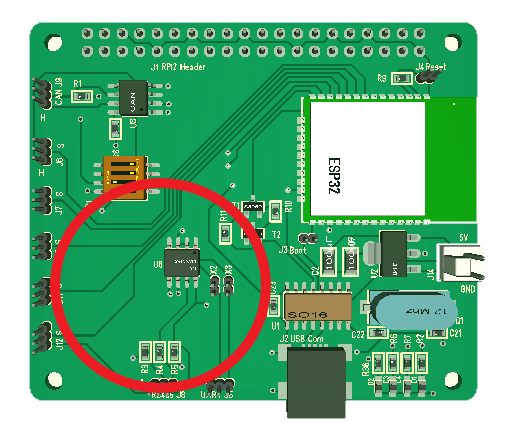

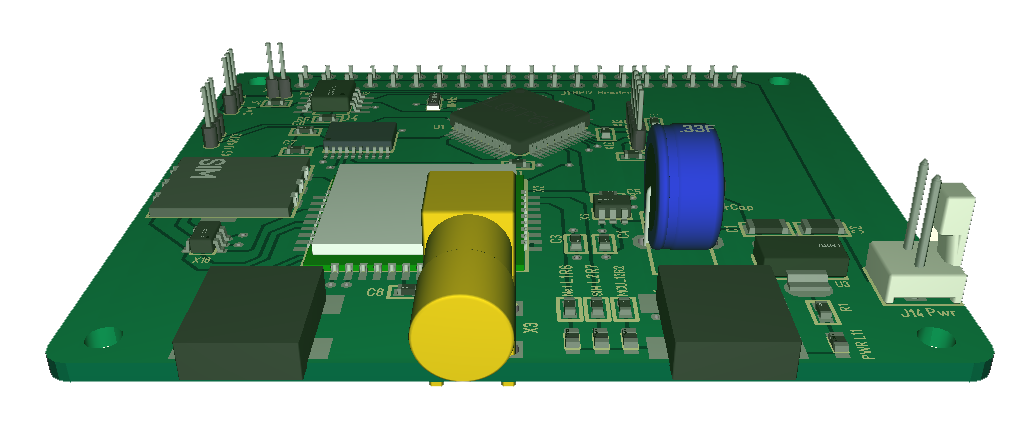

PSU requirement for SIM7020 is 500mA power peak, but this should be achievable through standard PSU. At some point I need to add a PSU module supporting my Hat’s, but that is for later concerns. To support the power and avoid a power dip I added space for a 0,33mF Supercap on the 3.3V. This should significantly reduce the peak current + the hole-though connectors can actually be used for a battery as well.

Debug is through USB or UART2, Firmware upgrade is only UART2 – a bit weird, but I have added both. Powering either of the USB’s will power everything to allow debug as needed with a single USB. ESD protection is added for VBAT (3V+, SIM card lines and UART2 lines.

This is my 7th Hat in the new format. I had no reference on the SIM7020E schematics, so will be exiting to see if this works at all. Was a bit annoyed over the UART’s from SIM7020E because they where 1.8V, so had to add a level shifter. Used TBX0108 in SO20 format from Texas Instruments, so will see how that goes as well. Luckily I have a test board on the way so I get to test NB-IoT before I dig into my own board.

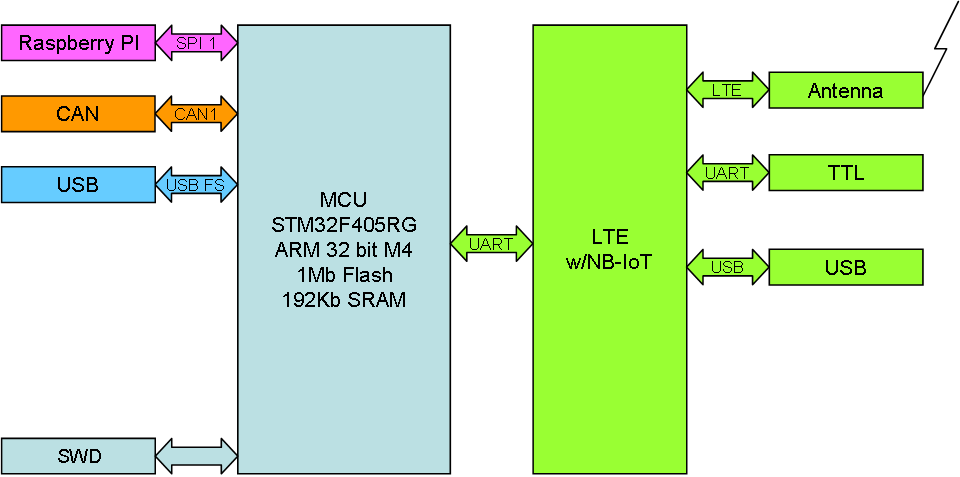

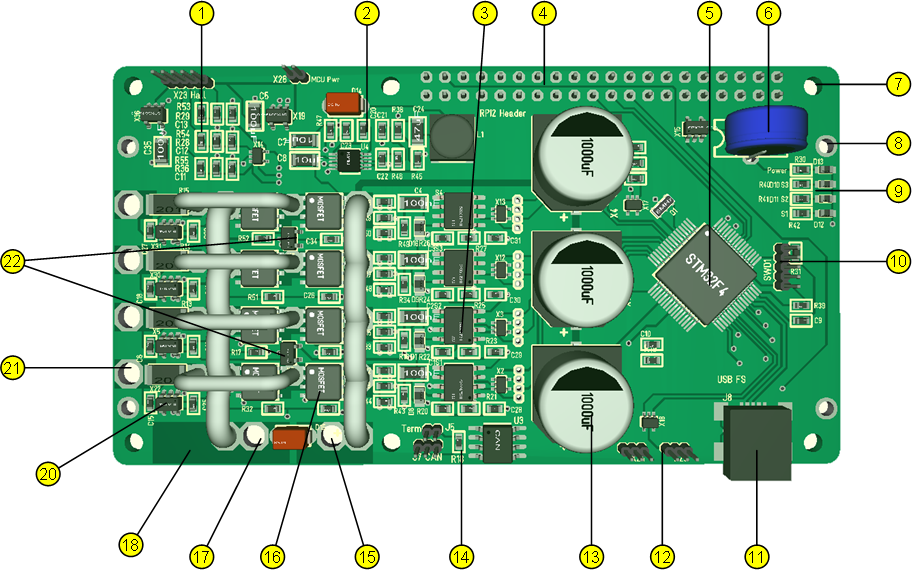

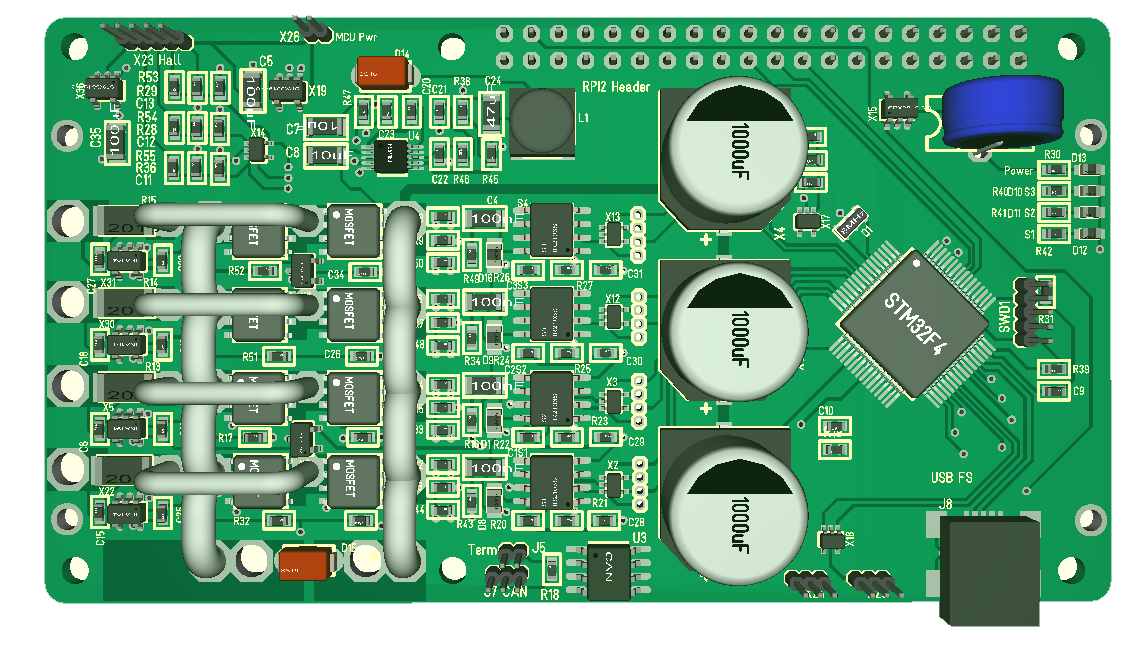

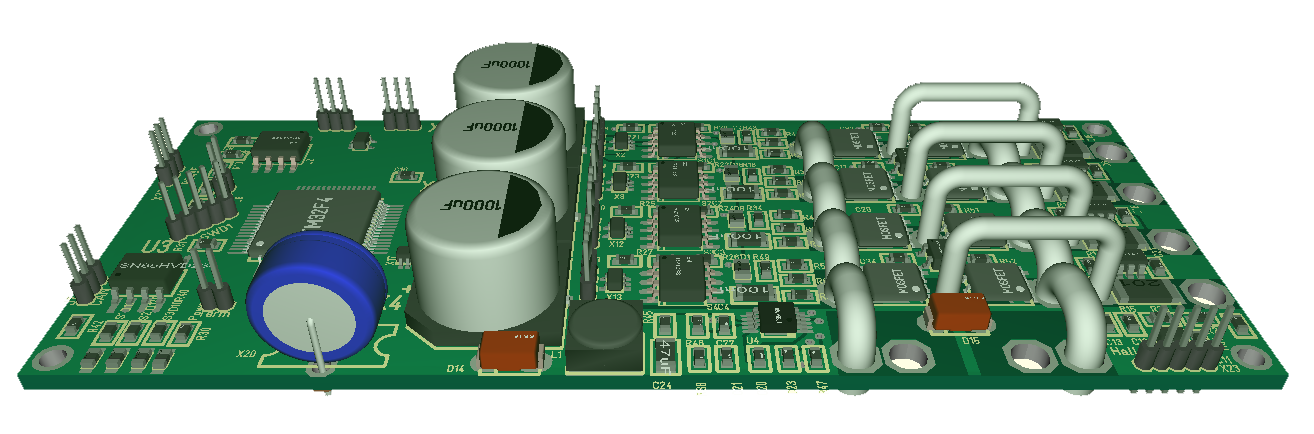

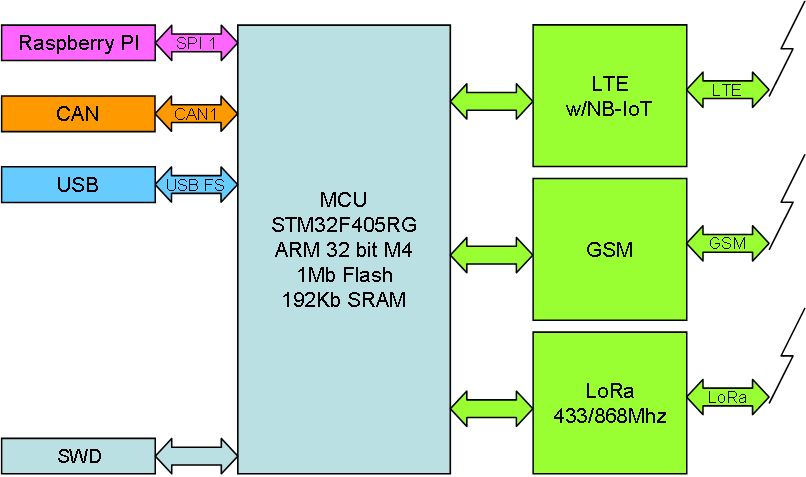

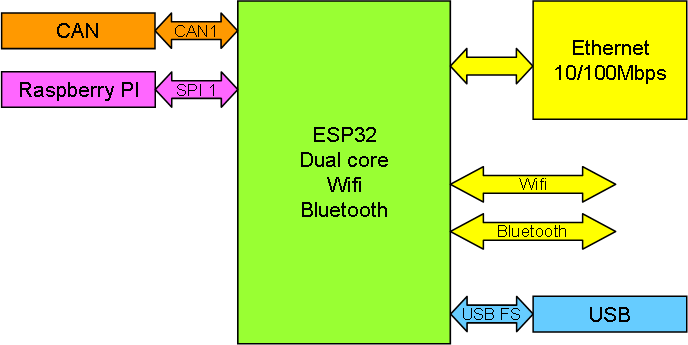

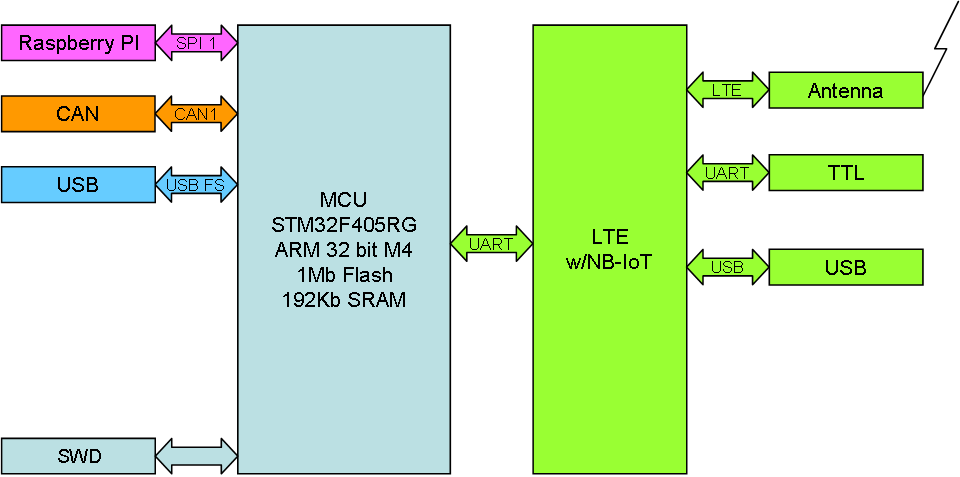

Functionality on NB-IoT uses a STM32F405RG to either connect on USB, SPI to Raspberry PI or CAN. Connection to SIM7020E is through UART on TTL level. Both UART’s are level shifted. The external UART is for Programming/Debug, while the extra USB also id for Debugging.

I have no experience using these modules, but I expect that I will be able to send/receive data using TCP/UDP at a speed of 26.15-68.5Kbps. It will be interesting to test.

Next out is GPS and LoRa Hat’s.