I have 2 CAN Adapters at present. One is the low cost USB Adapter and the other is the XPortHub.

The picture above show the smaller, single channel USB to CAN Adapter.

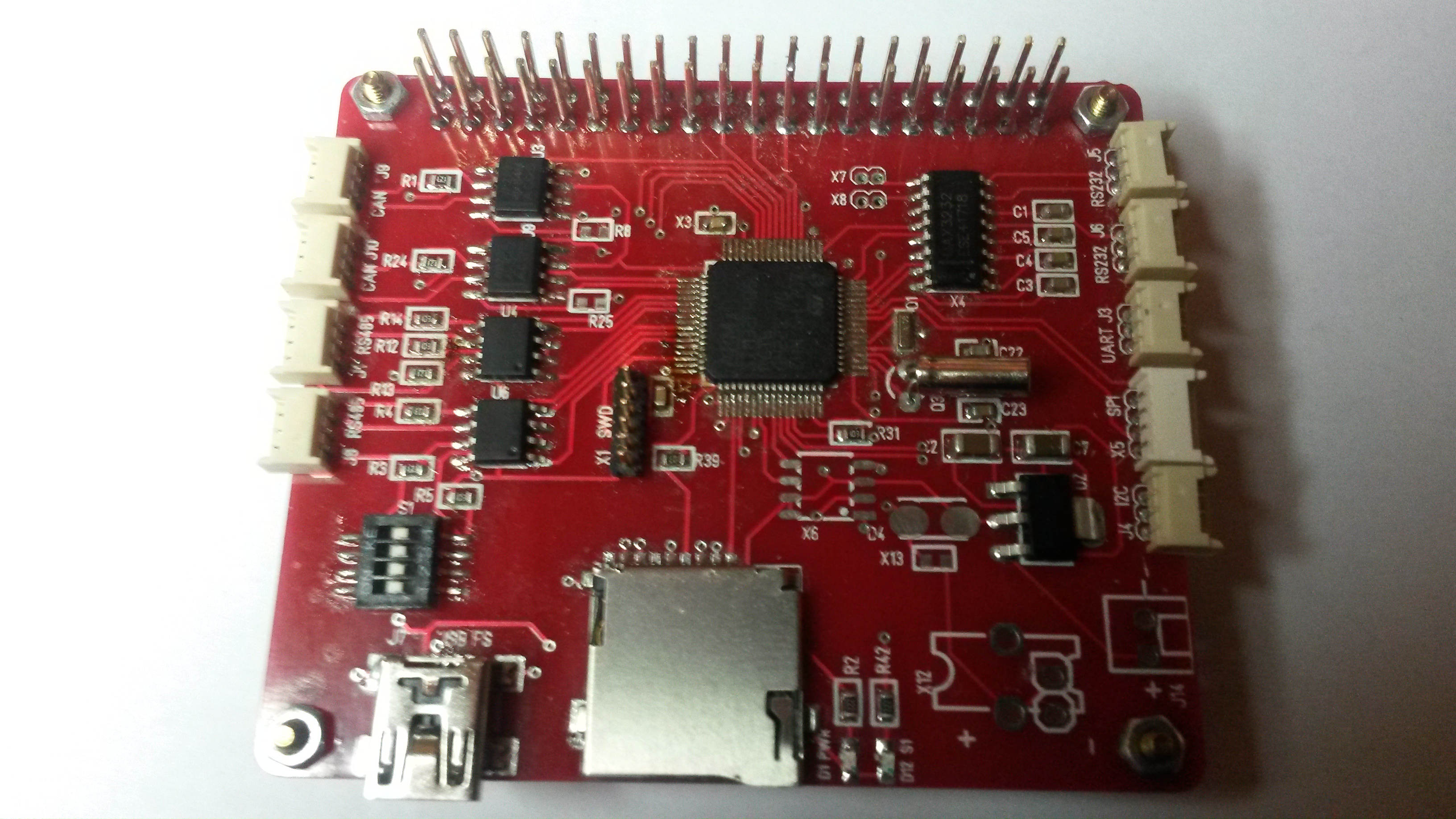

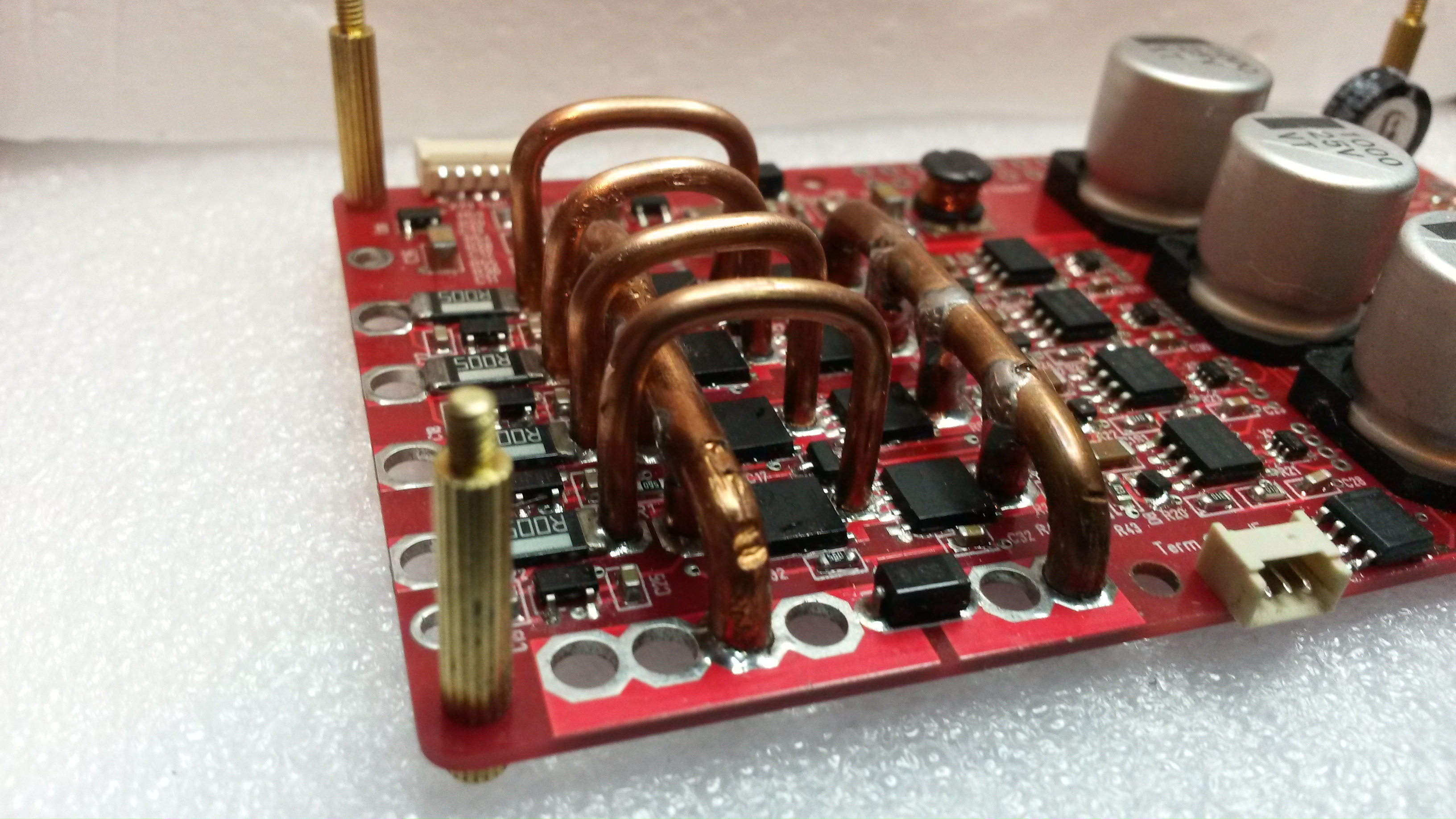

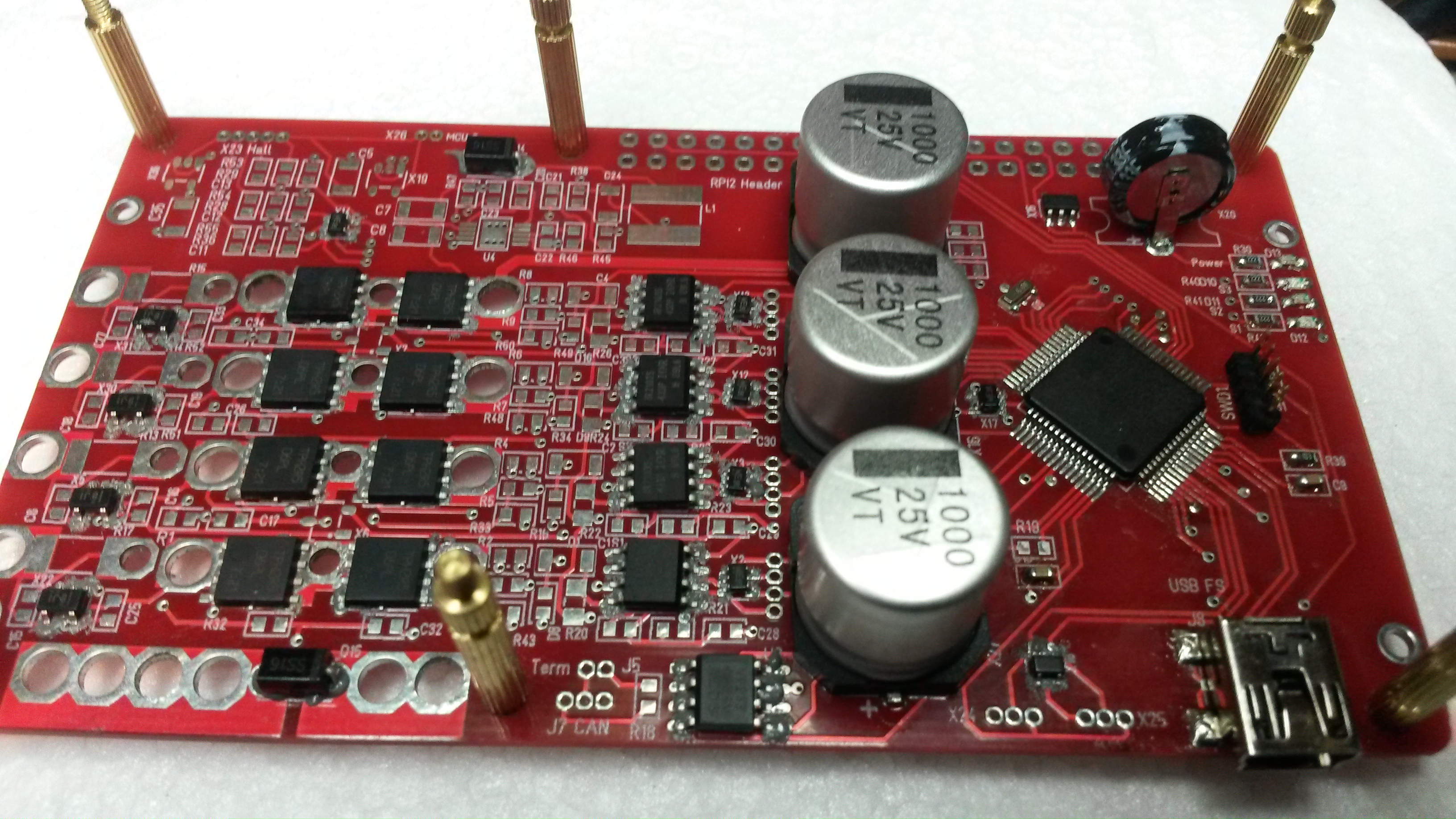

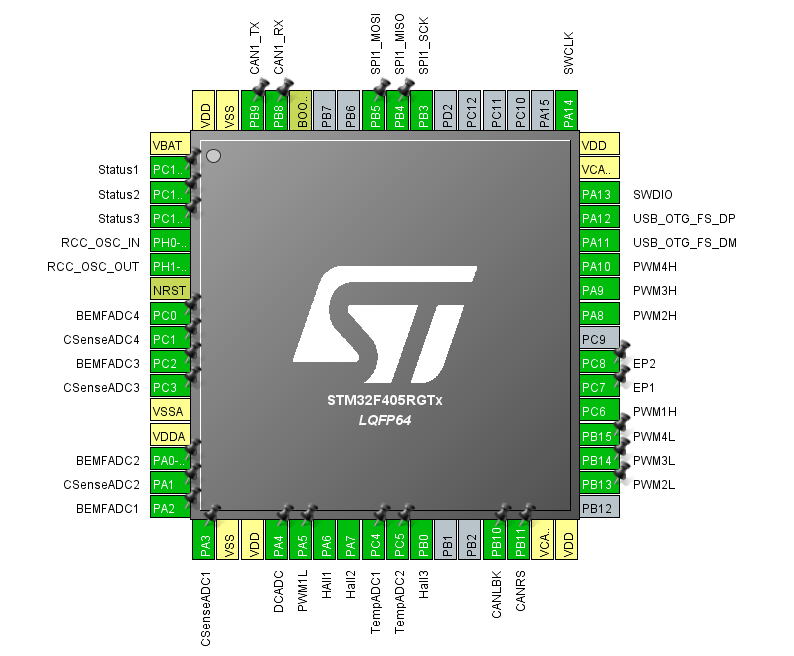

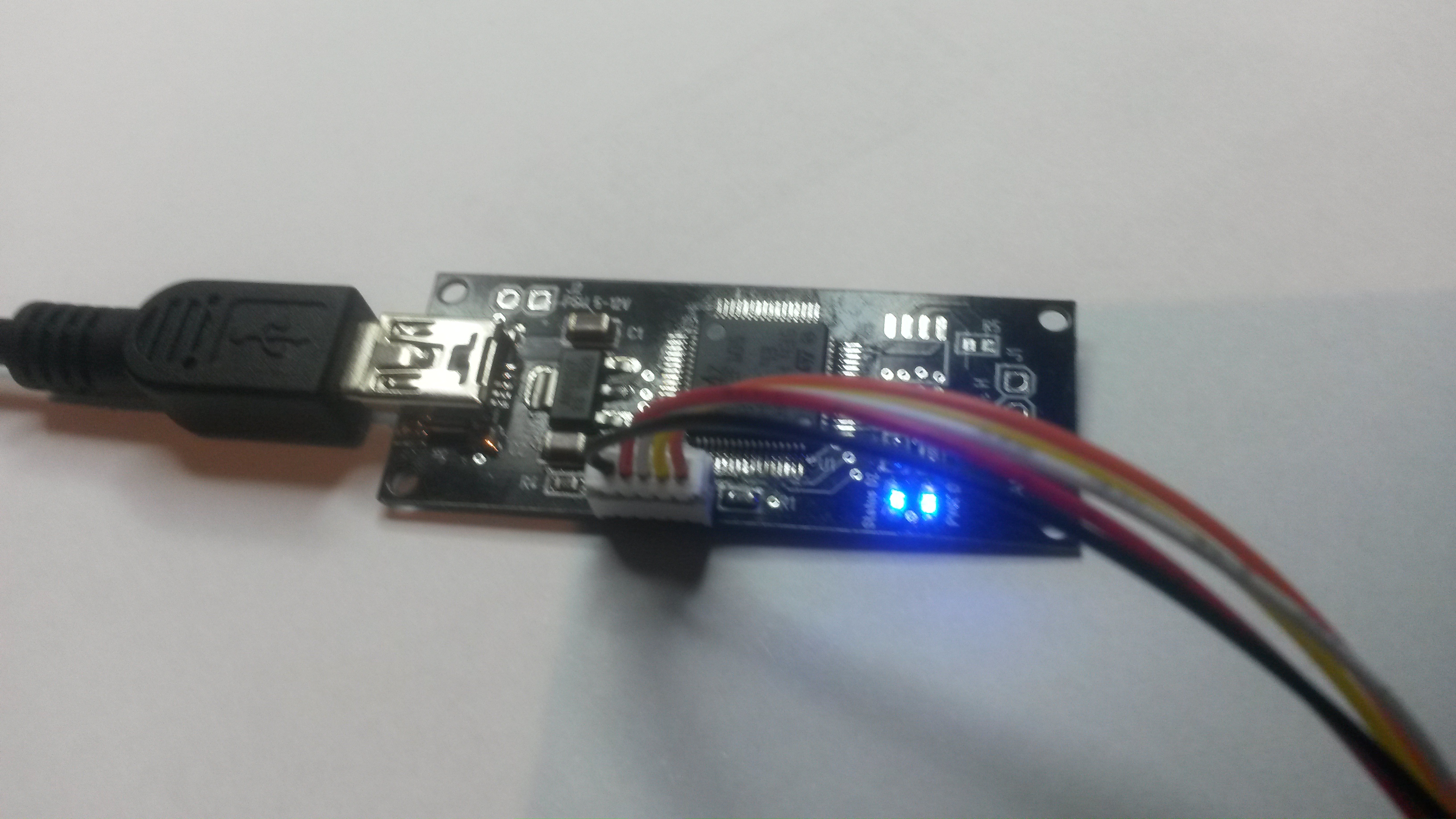

The picture above show the more powerfully XPortHub that provide USB, CAN, RS-485, RS-232, UART, SPI and I2C channels.

The USB to CAN adapter is designed as a low cost adapter while XPortHub is designed to be a component in a modular control system. But, they are both excellent USB/CAN Adapters.

The CAN ports offered are CAN-HS (High Speed). It actually also exist a CAN-LS/FT (Low Speed or Fault Tolerant). The HS bus uses 2 wires, while the FT version uses 4 as it includes + and – and schemes for communication if one of the twisted pair lines break. This is however rarely used as most systems prefer to just use 2 CAN ports for redundance