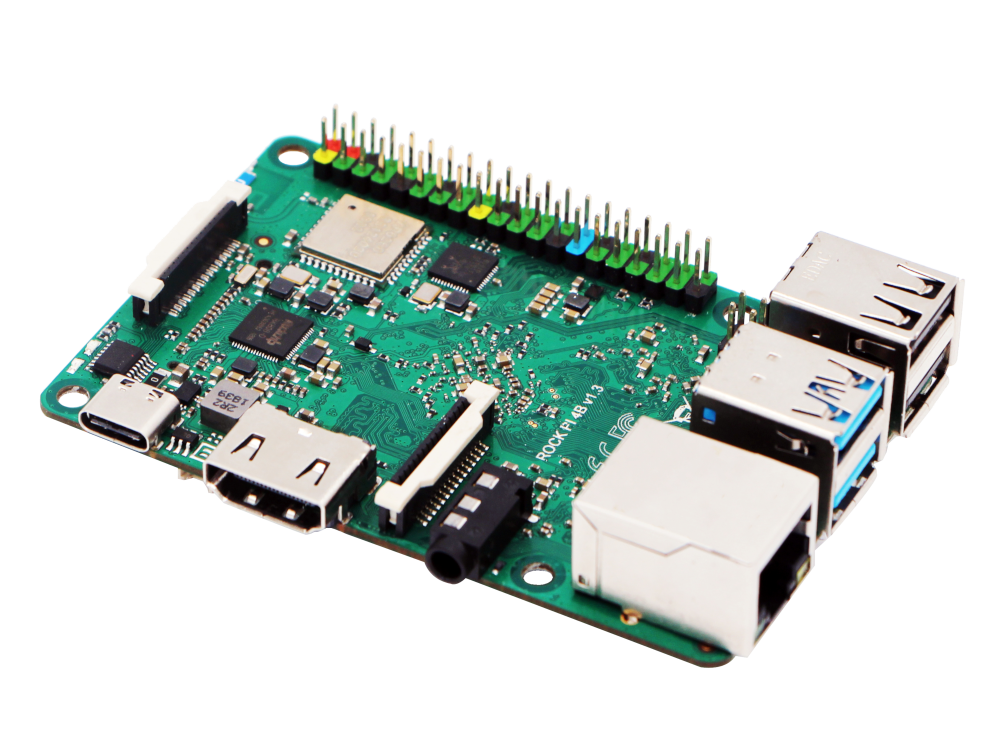

I accidentally came across “Rock PI 4 b” and first believed it was about Raspberry PI 4 as I realized this is a board based on Rockchip RK3399. It is very similar to Raspberry PI 4, but contain some very interesting differences. Of most interest for me is that the form factor and GPIO pin layout is compatible, meaning I can use my Hat’s on this directly. Lets outline some of the differences.

| Rock PI 4 b | Rasberry PI 4 b | |

| CPU | RK3399 | BCM2711 |

| Cores | 6 Cores

2 x A72 @ 1.8Ghz 4 x A53 @ 1.4Ghz |

4 Cores

4 x A72 @1.5 Ghz

|

| GPU | Mali T860;P4 | VideoCore VI 3D

500Mhz 32 bit |

| RAM | 2,4Gb | 1,2,4 or 4Gb |

| Micro-SD | Yes (128GB) | Yes |

| USB | 2 x USB3

2 x USB2 |

2 x USB3

2 x USB2 |

| USB OTG Switch | Yes | No |

| RTC | Yes | No |

| eMMC Socket | Yes up to 128GB | No |

| PCIE M.2 socket | Yes Support up to 2TB SSD | No |

| Ethernet | Gigabit | Gigabit |

| Wifi | Yes | Yes |

| Bluetooth | Yes | Yes |

| Sound | ? | 4-pole stereo |

| Camera Port | Yes | Yes |

| Display Port | Yes | Yes |

| HDMI | 1 x Standard HDMI | 2 x micro-HDMI

2 x 4Kp60 |

| GPIO | 40 pin RPI standard | 40 pin RPI standard |

| PSU | USB-C 5V | USB-C 5V |

| PoE | Possible | Possible |

| Price | 67$ (4Gb) | 55$ (4Gb) |

The eMMC interest me as it allows me to boot from Flash making this an interesting option for more commercial solutions. Other than that I must admit that 2 x HDMI etc only is of interest if you replace your desktop PC.